150°C DM/C -HS Centrifugal Ovens for centrifugal casting

Description

Centrifugal Electric Ovens for centrifugal casting

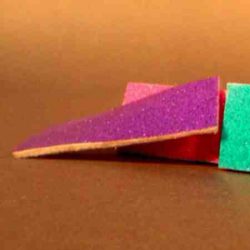

Ventilated Electric Centrifugal Ovens suitable for HIGH QUALITY MOULDED PARTS IN POLYURETHANE, SILICONE, etc.

Main features:

- Baskets for high rotation speed, made from treated steel, dynamically balanced with lapped work surfaces

- Inverter for adjusting drum rotation – control panel

- Thermal insulation for reduced energy consumption

- Finned and armored heating elements with high thermal efficiency

- Precision and uniformity of temperature

- With innovative air circulation system.

- On request: Customized basket sizes

- Very low operating noise level

- Stainless steel oven chamber (optional)

- Three oven models, complete with all accessories

- Safety devices certified for manual operations on the machine

Below catalouges and technical info :

Examples of heat treatment:

DM / C – HS – Max. centrifugal oven temp.: 150°C

Centrifugal ovens designed for the production of high-quality sheets of polyurethane, silicone, etc. The high-speed basket produces an item with a uniform thickness. Three models available for producing sheets with lengths from 2000mm. to 4000 mm.

Keywords (Max 5):

Partner & Company Description:

PU Consulting AB

Consulting – Distribution – NewDevelopment with PUspec24/7™ and PUspec. Sustainable Know-How and Transparent collaboration remotely to offer STRONG GREEN products and services.

Consulting

• PU Consulting AB have helicopter knowledge about sales, organisation, material, process and quality inspections.

• Specialists with many years experience from the industry. Academics with knowledge of how to optimize chemistry, process and design.

• Improve the product’s ecological footprint and pave the way for a circular economy

Distribution

• Material, machines and equipment

• We taylormade material, machine and equipment

• Used machines and equipmen , what do you need ?

• Improve the product’s ecological footprint and pave the way for a circular economy

New Development

• New Development of strong and green products.

• PU Consulting AB’s team and network are organized to work with the industry for new development.

• Improve the product’s ecological footprint and pave the way for a circular economy

PUspec24/7™

• Build your products and services Know-How BANK with our Remote Transparent Collaborations tools. One tool for production, audit, purchasing, quality inspections…

• We offer Consulting, Distribution and New Developlment support with remote solutions.

• Improve the product’s ecological footprint and pave the way for a circular economy

• Read more…

PUspec®

• Products and solutions tailored for customers. Tailor-made design, material, machines, accessories and automatic-process.

• Transparent information and specifications

• Improve the product’s ecological footprint and pave the way for a circular economy

• Read more…